If you’re a warehouse supervisor, shipping coordinator, inventory manager, procurement specialist, product manager (e-commerce and retail), or fulfillment services manager, you can expect to be charged with finding ways of reducing warehousing and shipping costs for the company. There are many different pathways to lowering those costs, and one of them is all about knowing how to leverage dimensional weight in order to make optimal packaging decisions, resulting in spending less on both warehousing and shipping, not to mention avoiding unnecessary packaging waste.

What is Dimensional Weight, and Why Does it Matter?

Many people still think the single factor driving the cost of shipping a package is its weight. While that may often seem like it’s true, it’s not always true. The other factor that comes into play is a package’s dimensions. The thinking is this: When shipping carriers set rates only by the weight of a package, it becomes less and less worth their while to ship lightweight or low-density packages because of how much room they take up in the shipping vehicle relative to their weight. For example, think of a lightweight but bulky comforter for your bed. Relative to its weight, it’s going to take up a lot of room on a truck.

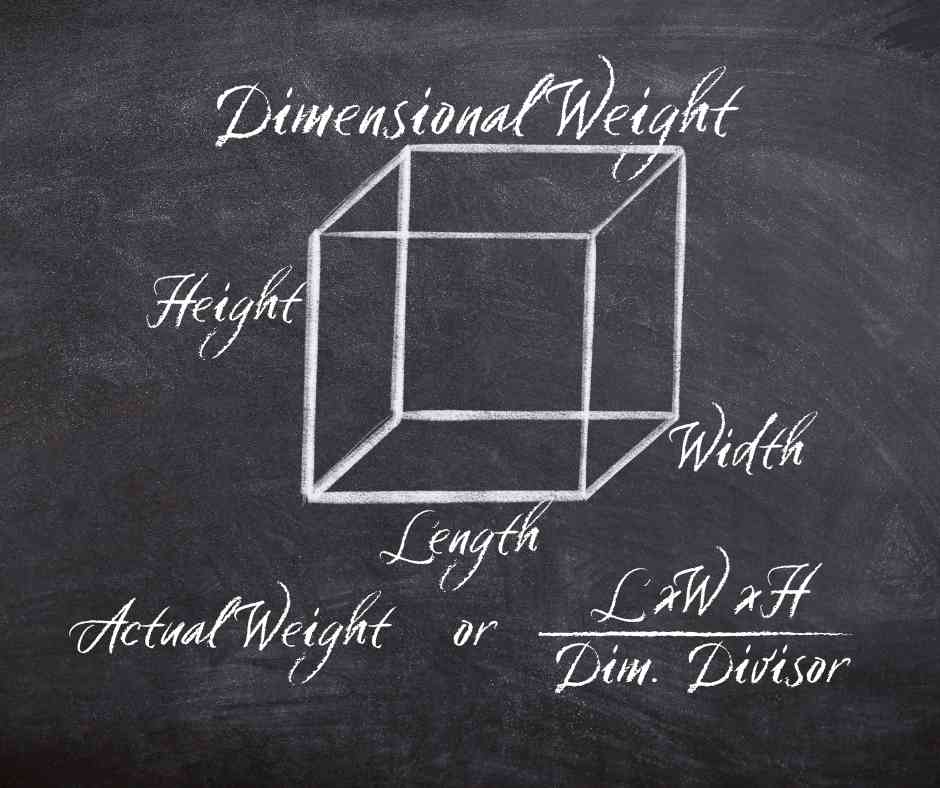

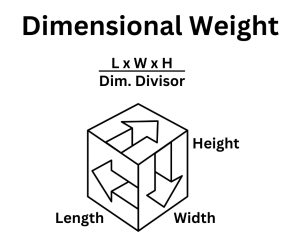

To alleviate these issues, the worldwide shipping industry, as of around 2015, has adopted an additional way to set shipping rates called dimensional weight or volumetric weight. It’s a technique for commercial freight carriers and shippers to estimate a package’s weight based on its dimensions, meaning length, width, and height. In the United States, the major carriers (UPS, DHL FedEx, and the USPS) all started using dimensional weight as an additional method for calculating shipping charges.

Armed with these two pricing techniques of actual weight and dimensional weight, each carrier will use both methods and then go with the one that results in a higher shipping charge. Needless to say, this is not what retailers want to be the case! They would much rather the choice be based on which method results in the lower rate to ship the package. Alas, all the carriers are choosing the higher of the two.

An example presented on the Wikipedia page about dimensional weight makes the situation all too clear: “Dimensional weight favors shippers of dense objects and penalizes those who ship lightweight boxes. A box of unpopped corn kernels will likely be charged by gross weight; a box of popcorn will probably be charged by its dimensional weight. This is because the large box of popcorn takes up a lot of space but does not fill up a vehicle’s capacity in terms of weight, making it an inefficient use of space.” In other words, shipping air doesn’t make good business sense for freight carriers!

Calculating Dimensional Weight

While this concept of dimensional weight may feel a bit esoteric, if you’re an online retailer shipping products to customers, it’s something you want to know about because it may be having an outsized impact on how much you’re paying to ship your products to your customers. It’s worth knowing how to calculate dimensional weight so you have a better knowledge of why your carrier charges what they charge; then, you can also decide to do something about it with the goal of reducing your shipping costs.

Let’s revisit our early days of learning geometry. Volume, for a standard rectangular package, can be found by multiplying the length x width x height (L x W x H). Be sure to round all measurements up to the nearest whole number. Now, take that volume and divide it by something called a Dimensional Divisor. What is it? A number created by carriers to help find dimensional weight. By default, it is typically 166 or 139, depending on the carrier. Round your result up to the nearest whole number, and there you have it:

You have found your dimensional weight!

Okay, so can we ship a heavy item in a small box to cheat the system? No. Even though we found the dimensional weight, every package still has an actual weight. So the carrier compares the Dimensional Weight and the Actual Weight (rounded up—always up, never down—to the next highest pound) and chooses the highest as what is then called the Billable Weight. This is where you can apply the rates you negotiated with your carriers to find out the true cost of your package.

Leveraging Dimensional Weight into Better Business Decisions

With great knowledge comes great responsibility. The good news is that there are all sorts of ways to take your newly found knowledge of dimensional weight and leverage it into better business decisions that will save precious resources at your company. Here’s how:

Track Your Weights: You’ll want to know the weight of your products and the packing and shipping materials. Let’s say your product weighs 1.5 pounds, your packaging container is .25 pounds, and your packaging materials weigh an average of around .20 pounds. So, you have a 2-pound package, after rounding up. Sometimes, however, your packer gets carried away and adds a little bit too much packaging material, thinking they are doing a good thing by adding extra protection. Maybe they add .30 pounds of packaging material. Now you have a 2.05-pound package, which (thanks to rounding up) becomes a 3-pound package, costing significantly more to ship. You see how this can add up quickly to way more shipping costs than you should be paying, all because of a simple but bad decision.

Analyze Your Packaging: It is important to know the average dimensions of your average orders so you can be very intentionally precise in shaping your packaging around that. If you have mostly 1, 2, and 5-unit orders, then create specific packaging that fits those average order sizes. If you have durable but flexible items such as clothing, consider paper or poly bag mailers. Shaving just an inch off any dimension of your packages can end up saving you a surprising amount of money, but just be sure to consider the average actual weight in your analysis as well. Remember, you have to compare actual weight to dimensional weight and go with the higher of the two because that’s what you’ll be paying for.

Negotiate your Dim. Divisor: Remember that weird number we mentioned earlier called a dimensional divisor that goes into the formula for calculating dimensional weight? Don’t be shy about bringing it up when negotiating rates with your shipping carrier(s). Since algebra tells us that a higher dimensional divisor is better, it is an easy way to reduce your dimensional weight by saying, “Hey, so if you really want my business and want to keep my business, how about increasing that dimensional divisor?” The most common numbers are 139 and 166. What should you suggest? Ask for it to be 194. You may be surprised how willing the carrier is to grant your request.

Additional benefits that flow from paying greater attention to dimensional weight and using it to optimize packaging and shipping materials include the following:

- Optimized Warehouse Space: A happy side benefit of retooling your shipping packaging to optimize it (typically by reducing it) for cheaper shipping means your packaging and shipping materials won’t be taking up as much space in your warehouses, resulting in further cost savings.

- Enhanced Packaging Efficiency: Tailoring packaging to minimize dimensional weight without compromising product safety can lead to more efficient packing strategies and less wasted packaging and shipping materials.

- Better Budget Forecasting: With accurate dimensional weight calculations, inventory managers can more effectively forecast shipping costs and budget accordingly.

- Increased Profit Margins: Lower shipping costs through optimized dimensional weight can contribute to higher profit margins on products sold.

- Enhanced Customer Satisfaction: Efficient packaging and shipping can improve delivery times and reduce shipping costs for customers, which always makes them happier. In fact, if you fully leverage this information as much as possible, you might be able to reach the holy grail of what every customer really wants, which is free shipping! Learn more in our blog article: Can You Afford Free Shipping?

IDS: A 3PL Fulfillment Provider Who Will Save You Money

At IDS, we take great pride in helping each client achieve the most efficient product packaging along with optimal shipping of those products to customers. We will gladly help you answer this question: What Shipping Packaging is Right for Your Business? After all, you’ve just learned from reading this article how important it is to leverage dimensional weight into all kinds of better business decisions, and we can handle all that for you. You might also be interested in learning more about the importance of branded packaging in our blog article, Branding the Inside of the Box: Necessity or Luxury?

IDS offers a full range of 3rd Party Logistics Services, including the following:

- Strategic US Locations: IDS has fulfillment centers in Utah and Indiana, enabling two-day shipping to 92% of the US. This capability resonates with direct-to-consumer (D2C) brands wanting fast shipping.

- Value-Added Services: An array of IDS value-added services means we can meet your company’s changing needs. These services include kitting, returns management, personalization (notes, greeting cards, gift wrapping), embroidery, labeling and repackaging, custom-branded packaging and packing slips, cross-docking, drop shipping, QA product checks, and more.

- Advanced Integration Capabilities: At IDS, we use a warehouse management system (WMS) to offer our clients real-time visibility along with integrations for most major shopping carts. This technical prowess can make operational processes seamless for D2C brands, ensuring easy setup and robust operational monitoring.

- Scalable Platform: The IDS platform is specifically designed to scale with your brand as it grows, meaning you won’t have to worry about outgrowing your fulfillment partner.

- Cost Savings with IDS ProParcel: Through our ProParcel shipping solution, IDS aggregates shipments to negotiate better rates, and we are always happy to pass those savings on to you.

- Personalized Customer Approach: At IDS, we pride ourselves on taking a highly collaborative approach with each client. We’re not just a 3PL fulfillment provider, we’re your partner in business.

- Transparent and Competitive Pricing: We understand your company has to be budget-conscious. IDS provides cost-effective solutions because of our strategic locations, automation technologies, and significant shipping discounts.

- Responsive Support and Communication: IDS aims for excellence in customer service with every client by focusing on providing clear visibility and prompt resolutions to any issues, backed by our advanced WMS, to ensure you’ll have an open line of communication and quick support response when needed.

Ready to discover the IDS Advantage? We look forward to meeting you and showing you how we can help. Reach out to us today through our Contact page, or feel free to call us directly at 866-576-0576.

Last Updated: Aug 15, 2024