Saving Money on your Fulfillment During Economic Uncertainty

Are we on the verge of recession? In a recession? I will admit I am no economist, so I’m not going to say. But there seem to be signs pointing to yes and others to no. Therefore, businesses everywhere are looking to save money, either to help their bottom line or not have to pass the price increases to their customers. But do we really need to be in a recession to pay attention to saving money? I think not! Below are some tips that have helped our customers save tens of thousands of (if not more) dollars on their fulfillment.

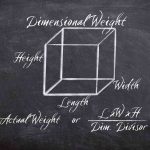

Tip 1: Watch your weight! When you look at your FedEx, UPS, USPS, DHL and other carrier reports, you should see a weight column. It is important to know how many packages are being shipped at a given weight. Use this information to find your most common weights, your “sweet spot”. Finding your sweet spot is important because that is where you should focus when it comes time to negotiate with your carriers. Let’s say your average shipment weighs between 1-2 pounds. Try to get your cost in that range as low as possible. In exchange, give them some wins in other areas. Who cares how much they will charge you for a 25-pound package? You hardly ship any! Also, beware of this funky thing called dimensional weight, as it can sometimes trump actual weight. Check out our article for what dimensional weight is and how to watch out for it.

Tip 2: Location Location Location! On those same previously mentioned reports, you should also find the zip codes you ship to. These zip codes can be used to find the most efficient location to ship from. The first three numbers of a zip code include the national area (think region) and the section of that region. Let’s say you are a New York-based business that ships primarily to New Yorkers, then, sure, it may make sense to continue to have your operations based out of New York. But as your business grows and your clientele expands, analyzing this data would tell you where the best place to place your distribution center would be to minimize zones. I can even save you some time if your customers are mostly evenly spread out throughout the U.S., two distribution centers can be enough. One in the midwest and another in the west/southwest is perfect. Take it a step further and find cities with low cost of living for lower wages (such as Indianapolis and Salt Lake City), and boom, I just saved you money in 2 categories in 1 tip! Don’t have the capital investment for a distribution center? We’ll revisit that later.

Tip 3: Negotiate your Rates! Some carriers offer more attractive prices for certain weights than others, and you would literally be throwing away money if you chose to go with the more expensive option. However, when you negotiate with your carriers, let them know how much you are spending with their competitors and that you would be open to moving that business to them if they can offer the best price for a given service. Every carrier is always looking to increase its business and will likely offer better rates if it can earn those competitors’ business. You can even use carriers’ offers against each other to get the best price, but be careful, hold out for too long, and they may pull their offers. Again, this is where it is important to know where your sweet spot is, so you can focus your negotiation on it!

Tip 4: Work with a Fulfillment Partner! If you read the above tips and did not understand them, know where to get started to address them, or do not know where you were going to get the time of day to execute them, do not worry, you are not alone! Fulfillment companies are here to help handle all the previously mentioned analysis, negotiation, and more. Concerned about labor management? Worry no more. Fulfillment companies can add and subtract management and labor as business ebbs and flows, reducing the risks to your company. Remember the capital investment needed for a conveniently placed distribution center? Not needed when working with a fulfillment partner. But what happens when you need more space? Just let your fulfillment partner know. Whether it be an additional couple thousand square feet or a new building, as long as there is justification, they should be happy to accommodate!

Well, there you have it. As money gets tighter and tighter, these tips should be able to help find some extra dollars that you may not have known would have been salvageable. Looking for your fulfillment partner to help realize these savings? Contact IDS Fulfillment so we can learn more about your business and how we can save you money!